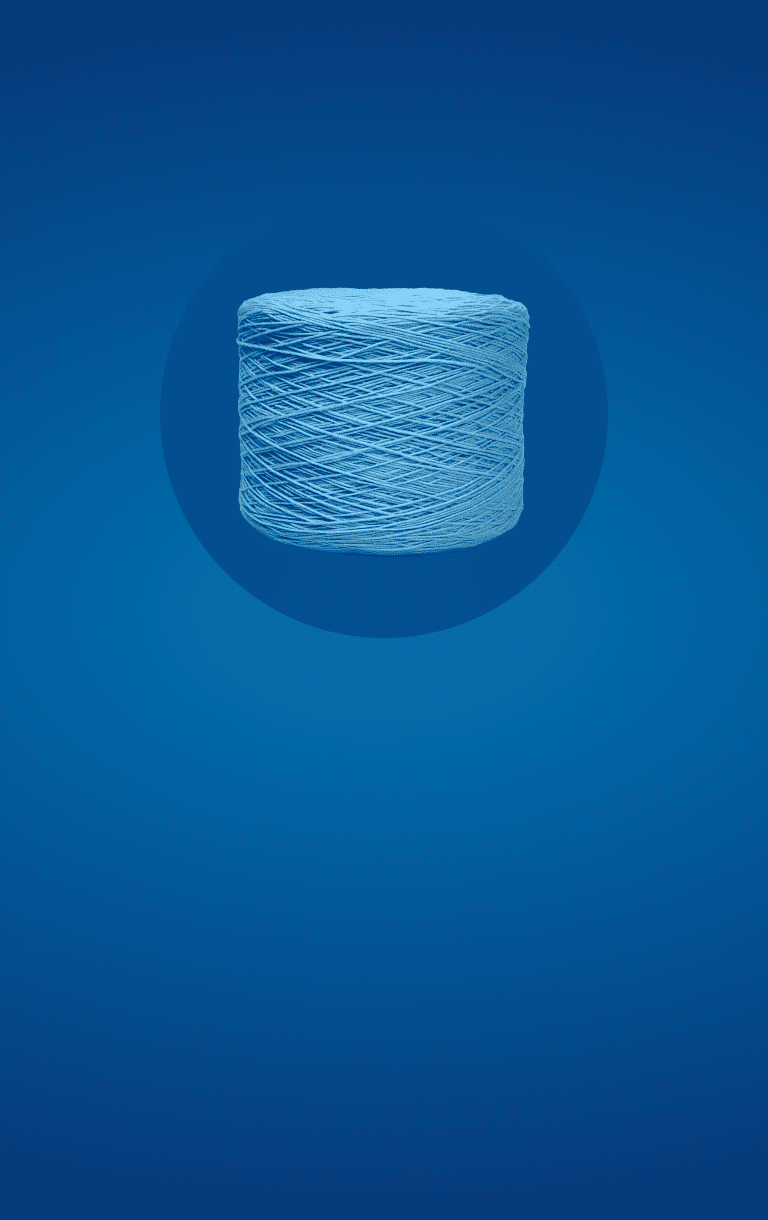

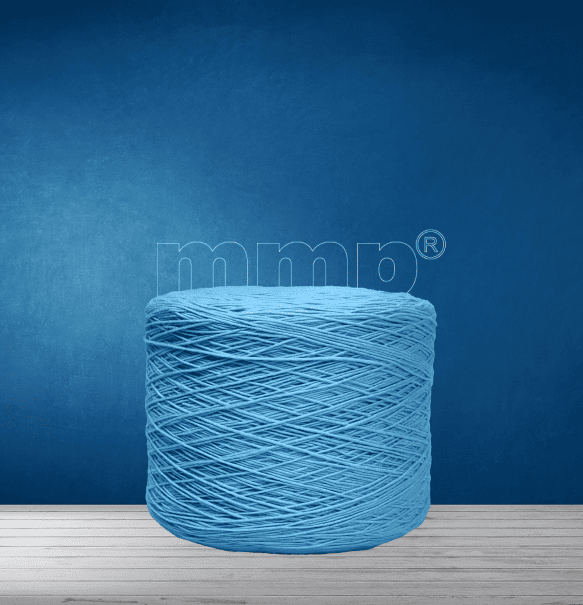

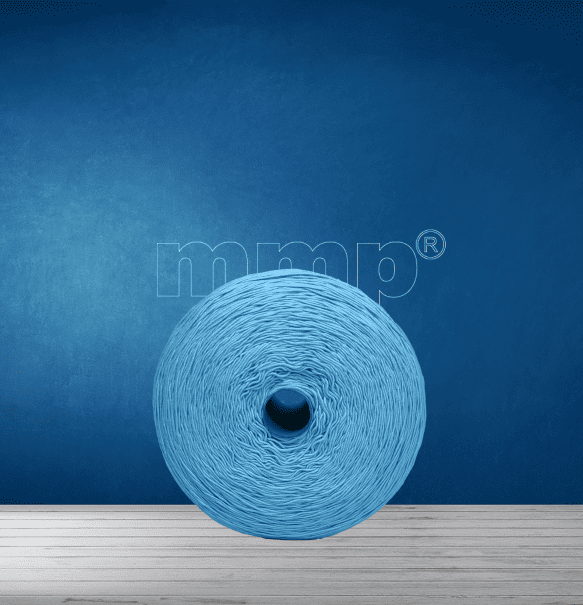

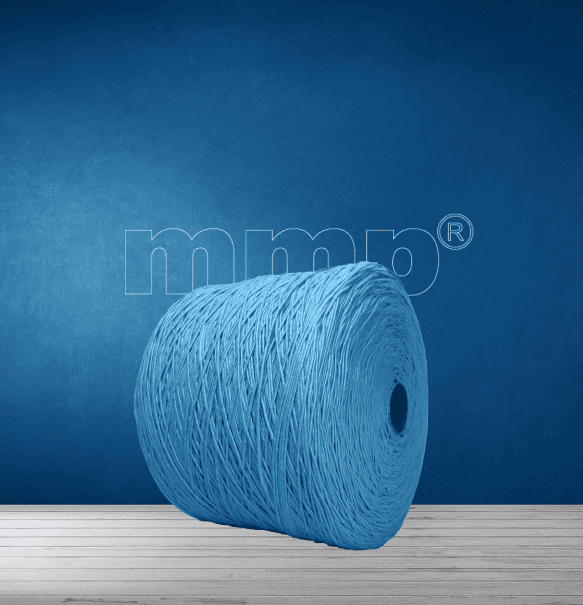

Anti-Microbial Polypropylene Filtration Yarn

High-purity melt-blown PP yarn with FDA-approved additives for superior microbial resistance in wound filter cartridges.

High-purity, melt-blown polypropylene yarn infused with FDA-approved antimicrobial additives. Discover our Antimicrobial Polypropylene (PP) Filtration Yarn, engineered for superior microbial resistance and optimized for producing wound filter cartridges.

| Feature | Yarn | Cartridge (e.g., 10”) |

| Base Material | ||

| Antimicrobial Agent | ||

| Denier Range | ----- | |

| Tensile Strength | ----- | |

| Cartridge Length | ----- | |

| Outer Diameter | ----- | |

| Flow Rate Capacity | ----- | |

| Micron Rating |

Our Antimicrobial Cartridge Yarn is a high-purity, melt-blown polypropylene yarn infused with FDA-approved antimicrobial additives. Specifically developed for wound filter cartridge manufacturing, this yarn offers enhanced protection against microbial growth during both production and operation. Its uniform structure ensures consistent filtration performance, while its antimicrobial properties help extend service life, improve hygiene, and maintain product integrity in critical filtration systems.

Antimicrobial Cartridge Yarn is vital for industries requiring sterile and contamination-resistant filtration solutions. In the pharmaceutical sector, it is used to manufacture filters that ensure bio-safety and compliance during drug production and packaging. In food and beverage processing, it supports the production of filters that safeguard product purity by preventing microbial ingress. The yarn is also ideal for high-purity water filtration, where it helps reduce bioburden and microbial fouling. Additionally, it is used in the healthcare industry for medical-grade filtration systems and in cosmetic manufacturing, where hygienic standards are crucial. Its durability and antimicrobial efficiency make it suitable for a wide range of industrial filter cartridge applications.

©Copyright 2026 mmp Filter. All Rights Reserved.