Menu

Pleated Filter Bags Manufacturer

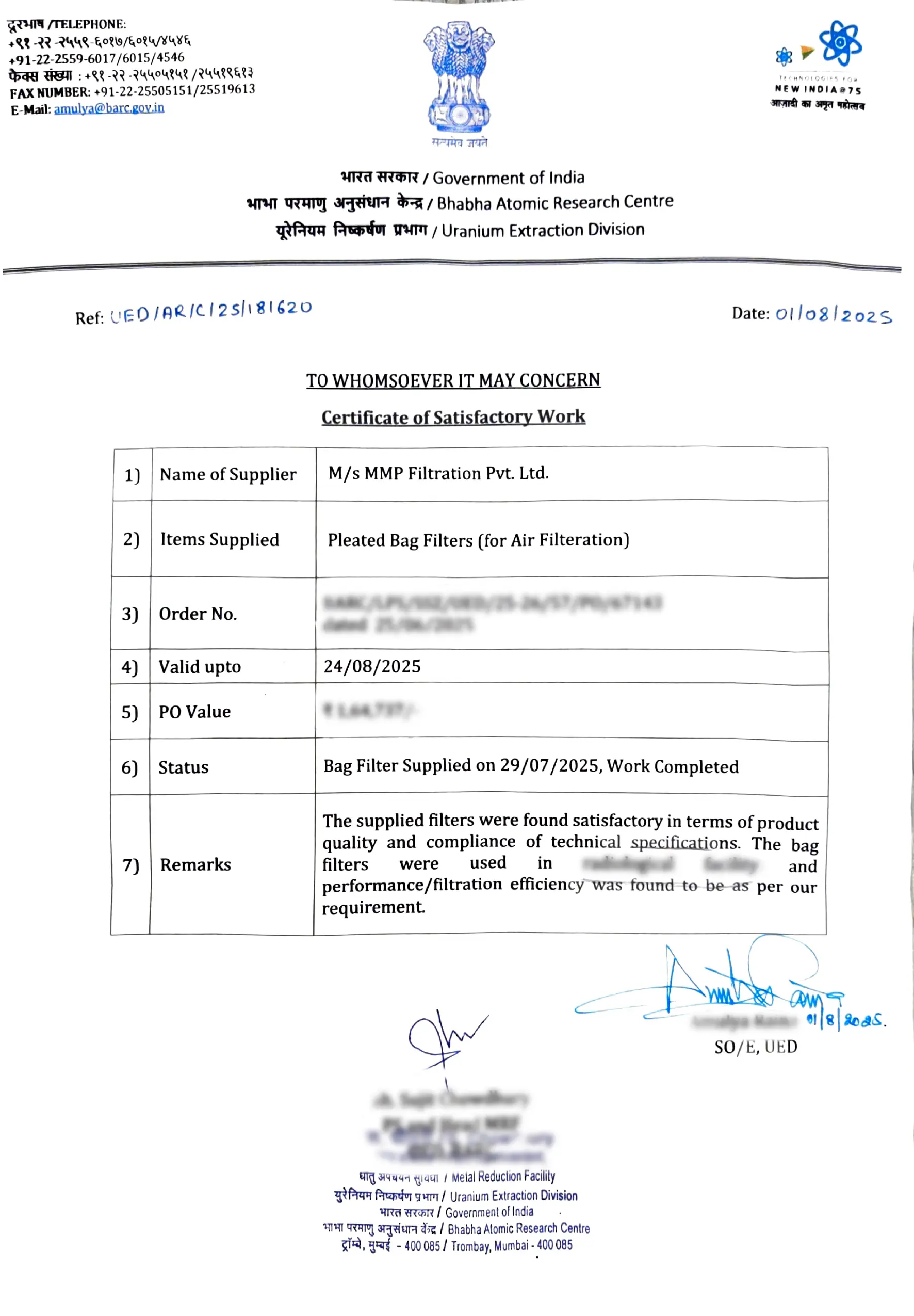

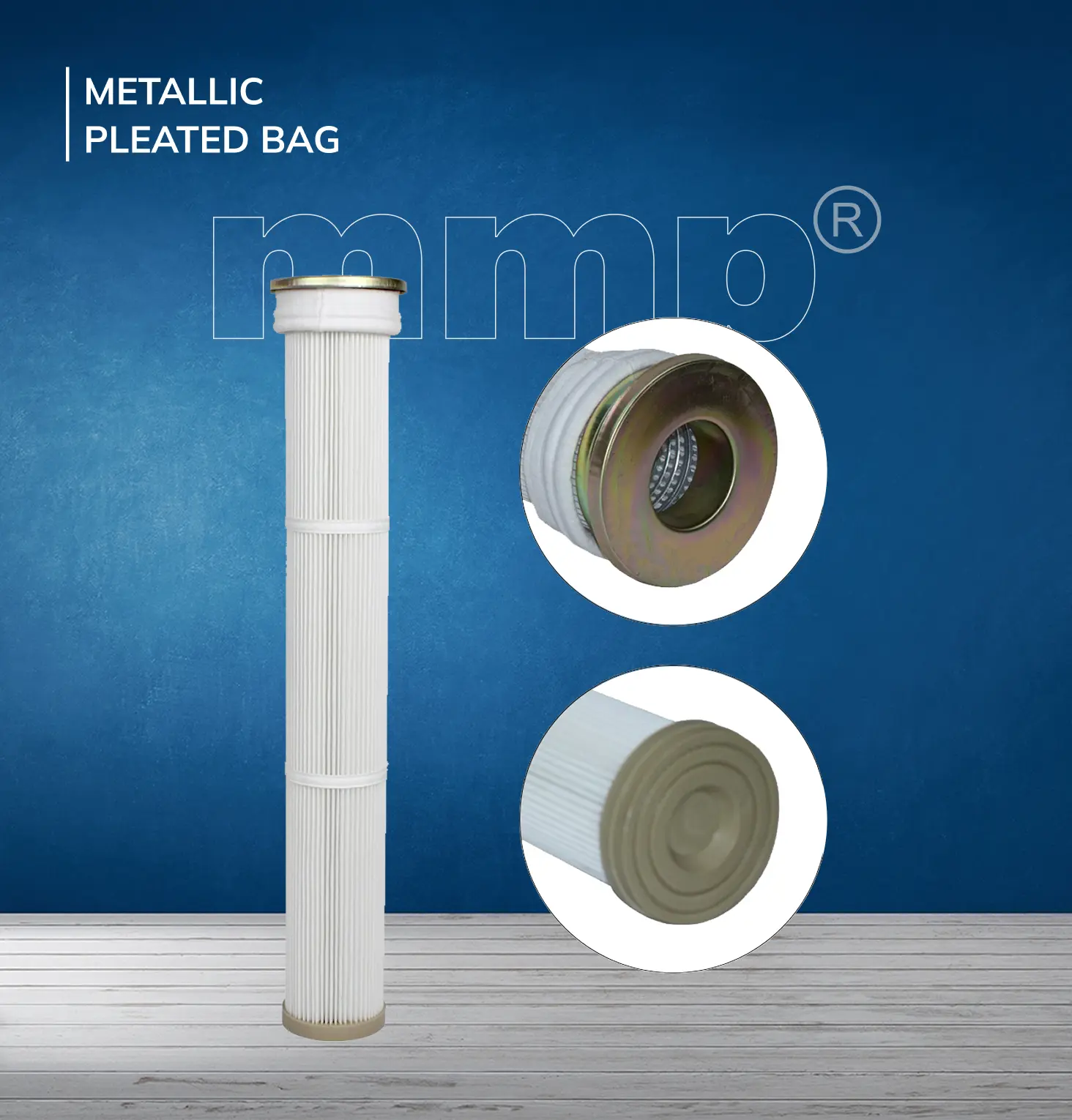

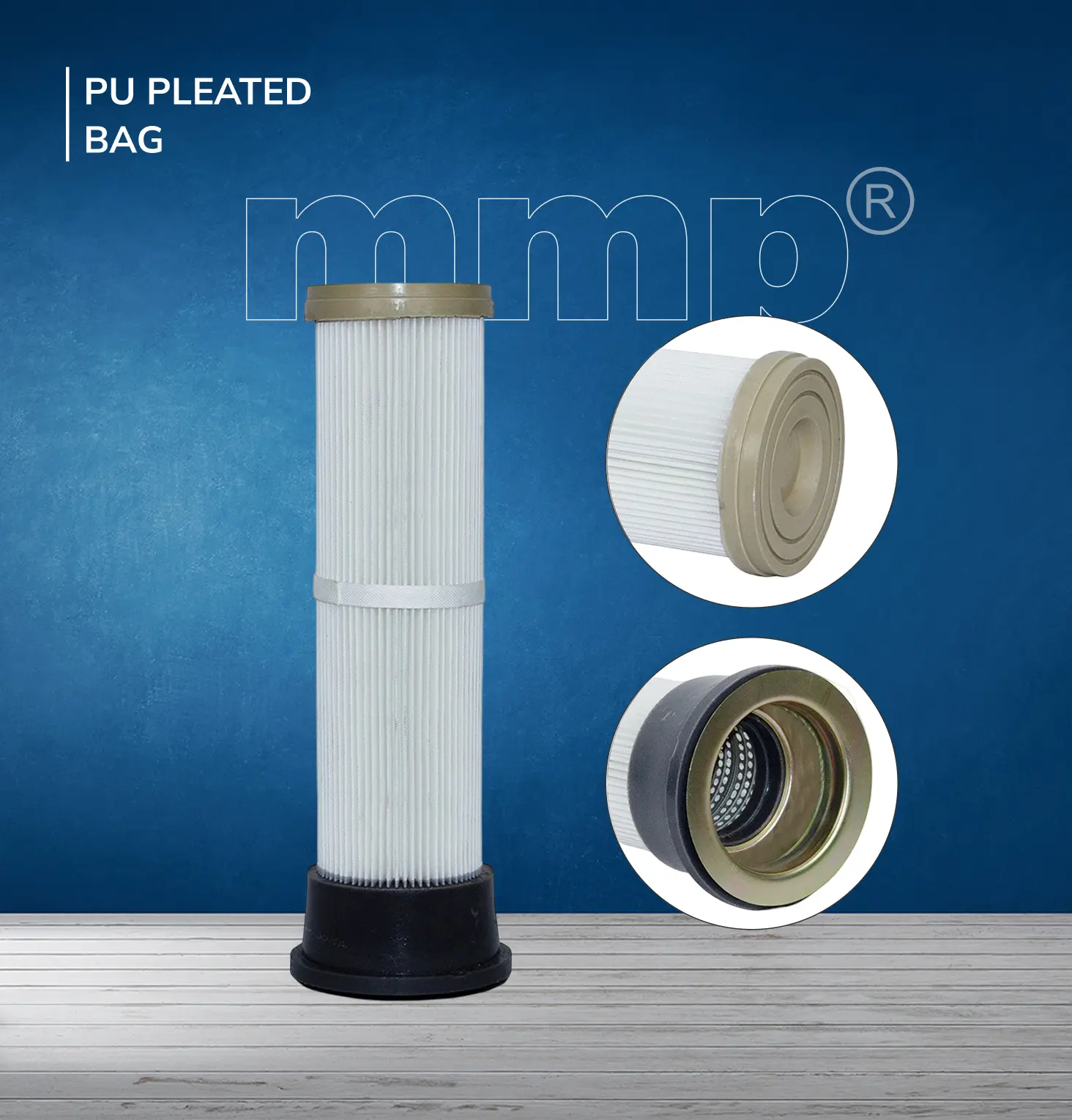

mmp provides a versatile range of Pleated Filter Bags, engineered with advanced technology for high-efficiency filtration and durable performance. Ideal for various industrial applications, these bags ensure effective dust collection, contributing to enhanced cleanliness and safety.

At mmp, we provide best quality pleated filter bags to both large and small-scale industries for over 30 years. Our extensive experience in the industry ensures that we understand the unique needs of our clients and deliver filter bags products that meet the highest standards of performance & durability. With a proven track record and a reputation for excellence, mmp is your trusted partner for all your dust collection requirements. If you have any questions about dust collector filter bags, please don't hesitate to contact mmp. Our filter bag specialists are ready to assist you.

Please inquire at mumbai@mmpfilter.com for the specification sheet.

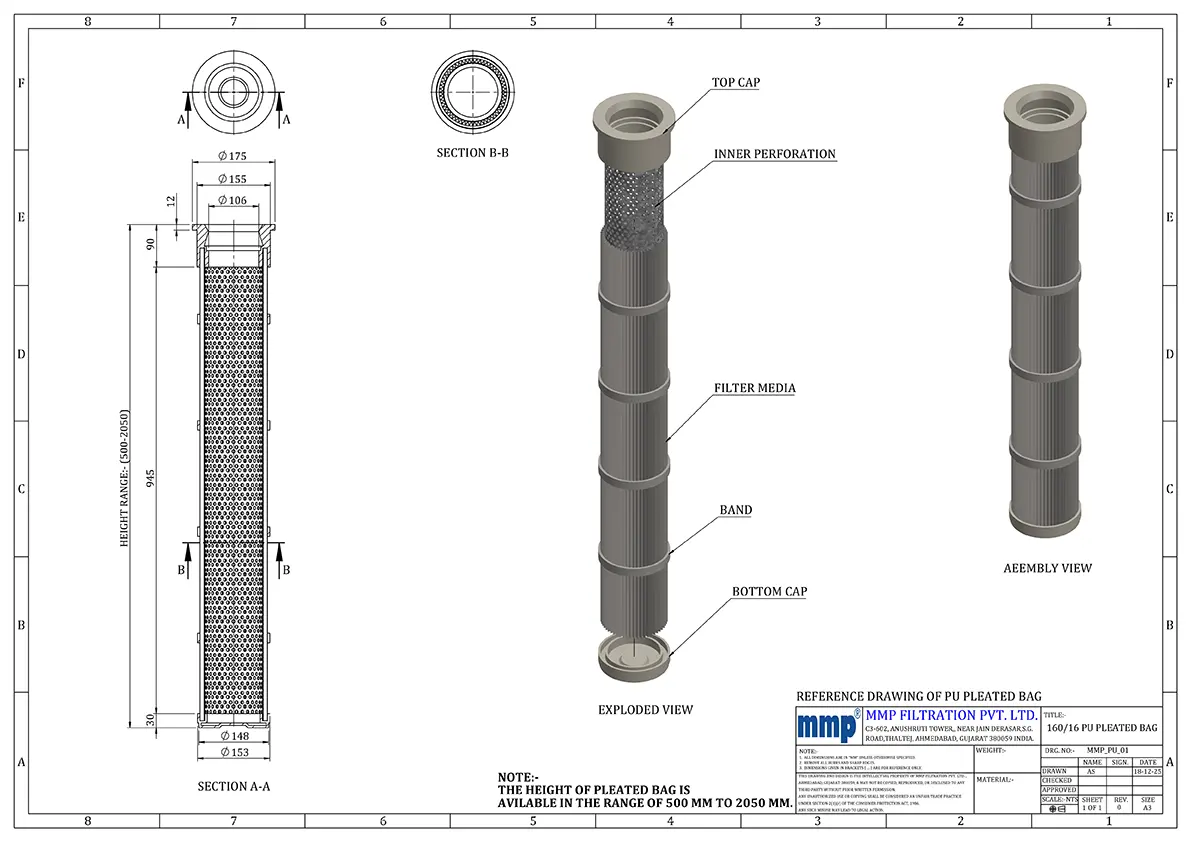

| Technical Name | Pleated Filter Bags |

| Fabric |

|

| Coating |

|

| Pleats |

|

| Top & Bottom |

|

| Fitment suitable for cell plate diameter |

|

| Length |

|

mmp pleatex pleated bag filters are engineered to deliver superior performance, boasting an extended filter life and higher efficiency compared to traditional filter bags. These filters are designed to maximize energy savings and reduce operational costs by enhancing filtration effectiveness. Their advanced pleated design significantly increases surface area, improving filtration efficiency and less frequent replacements. Ideal for a wide range of industrial applications, mmp pleated filter bags & Dust collector filter bags ensure cleaner air and optimized system efficiency.

mmp offers various features and benefits designed to enhance efficiency and longevity in industrial filtration. They are engineered to withstand higher working temperatures and effectively collect more dust, making them ideal for demanding environments. Easy replacement and customizable designs ensure seamless integration into various systems, with higher filtration efficiency. mmp baghouse collector filters provide reliable performance, contributing to cleaner air and optimized operational efficiency across industries.

- Cement Grinding Units & Silos

- Agricultural Sector

- Paint Manufacturing

- Textile Manufacturing

- Timber Processing

- Electricity Generation Plants

- Pharmaceutical Production

- Food and Beverage Processing

- Chemical

- Oil-Water Separation

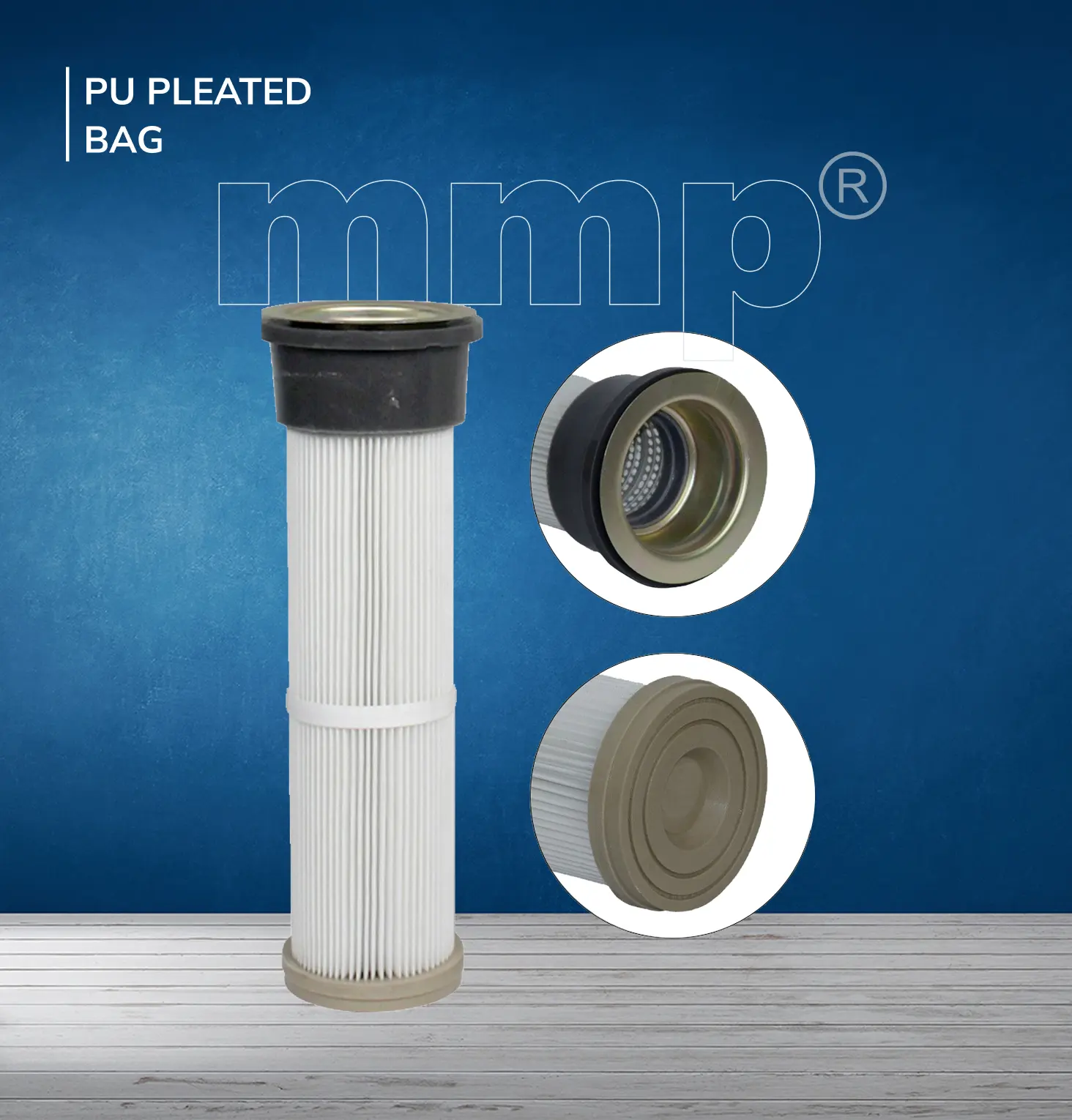

Customer Testimonial